|

By Roger Sims

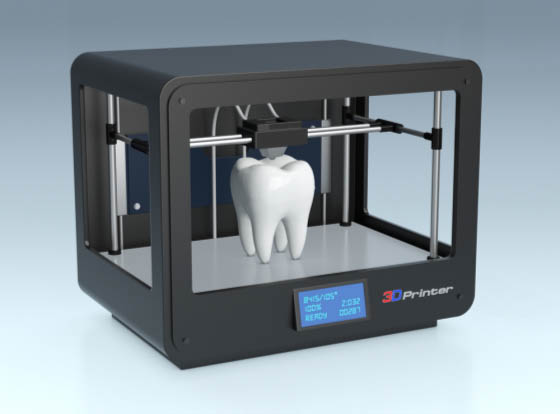

In the past few years, 3D printing has taken the world by storm. This technology has changed the way we make things, and companies are taking note. Virtually every industry—from manufacturing, to real estate, to fashion, to automotive—has taken advantage of the capabilities of a 3D printer. Another industry that is benefiting from 3D technology? Healthcare.

The healthcare industry is excited by all the possibilities. Until 2020, 3D printing in the healthcare industry is expected to grow 18% each year. The medical field is already using 3D printers to create custom implants, prostheses, and more. Many types of 3D printing—such as stereolithography, laser beam melting, electron beam melting, and fused deposition modeling—are being used to create medical devices.

This is just the beginning. The healthcare field is seeing other applications for 3D printers, such as drug manufacturing, organ implants, and dental applications. Ceramics, metals, bone cement, donor cells, and biomaterials can be used to create a variety of products to benefit medical and dental patients. Many of these materials are still very expensive but, as they become more widely used, their prices will drop.

Many companies are jumping in on this innovative technology and helping advance 3D printing in the medical field even further. These companies include 3D Systems, EnvisionTEC, Tevido BioDevices, Invetech, MicroFab Technologies, Digilab, Stratasys, and nScrypt. 3D Printing Is Cost-Effective People are living longer nowadays. Baby Boomers are aging at a high rate, which is putting pressure on the healthcare system. As a result, prices are rising for everyone. 3D printing offers a way to make healthcare affordable. Government subsidies and research grants are making this possible. Plus, the materials used in 3D printing are much less expensive than traditional materials. Instead of waiting for new medical technologies to have lower prices, 3D-printed medical products are reasonably priced from the start. For example, airway splints for babies who are prone to lung collapses take just a few hours to make and cost only $10. This creation is significant because the splints grow with the child, so they are made to last a long time. Because of the technology used in 3D printing, prices can afford to be lower. 3D printing uses layers of additive processes. A model is created, and the product is built with one layer on top of another. This process makes the final product precise, with less room for error. 3D printing also saves money because it focuses on addition rather than removal. Older manufacturing processes involve drilling, cutting, and chopping, which creates waste and added costs. 3D printing eliminates those issues. The Future of Healthcare Looks Promising While many potential medical advances are still in the experimental stage, the future looks promising for the medical industry, thanks to 3D printing. Some projects are going above and beyond current human capabilities and experimenting with tissue and electronics. For example, some scientists are experimenting with bionic ears that can hear radio frequencies the human ear cannot hear. This opens up a world of possibilities for tissue replacement. Soon, doctors may be able to customize replacements for human organs—and not only replicate them but enhance them. There will no longer be a need for organ donors, as surgeons will be able to print any organ they desire—kidneys, hearts, lungs, and livers, for a start. The Future of 3D Printing Is Already Here The good news is that you do not have to wait several years to see 3D printing in action in the healthcare industry. Many advances are happening as we speak, and some have been around for several years, now. In 2014, researchers combined 3D printing with facial scanning to create facial prostheses for those undergoing eye cancer treatment. A year later, researchers found out that printing implants could help cure bone cancer and infections. 3D printing has been used for other medical purposes. Tired of swallowing a boring, circular pill? Pills created by a 3D printer allow for various shapes and release rates. 3D printers have been especially useful in orthopedics. 3D-printed casts can help bones heal up to 80% faster. 3D printers have also created ankle replacements, with high success rates. With 3D printers, these types of medical treatments and products can easily become mainstream. North America is leading the way and has accounted for nearly 40% of the market share in 2014. Europe and Asia followed behind, accounting for a combined share of 37%. Devices and treatments that were once too expensive or too complicated to make in the past are now becoming more feasible and less expensive to make. 3D printers have the ability to take huge ideas and break them down into smaller pieces—literally and figuratively. 3D printing will revolutionize healthcare. Instead of waiting for an organ transplant, doctors can simply print one. Need a skin graft? Doctors can create one with ease. Prostheses and medical supplies can be easily printed. This reduces costs and increases the possibility of passing the savings on to the customer. While 3D printing has made huge strides in the healthcare field already, there is still a long way to go. Until you can print your own medical supplies, check out LoCost Medical Supply for all your healthcare needs. Sources: https://hbr.org/2016/03/3d-printing-is-already-changing-health-care https://3dprint.com/137461/3d-printing-healthcare-market/

0 Comments

Leave a Reply. |

AboutNews updates, tips, and guides on senior care, senior health, stress relief and a host of other caregiving related topics from the professionals at Ella Stewart Care. |

RSS Feed

RSS Feed